Research

Our faculty and graduate students are addressing the needs of society and the environment by developing solutions in water treatment, biomedical engineering, biofuels, nanotechnology, fluid mixing, renewable energy, and process optimization and control. From polymers that can help detect tumor cells, to tissue engineered for spinal cord repair, to aquifers designed to withstand climate change, revolutionary research is happening every day in the Department of Chemical Engineering.

“Thanks to Toronto Metropolitan University’s partnerships with institutions like St. Michael's Hospital, I can rapidly advance my polymer technology and research, and demonstrate its clinical value.”

Dr. Dae Kun Hwang

Professor, Chemical Engineering

Canada Research Chair

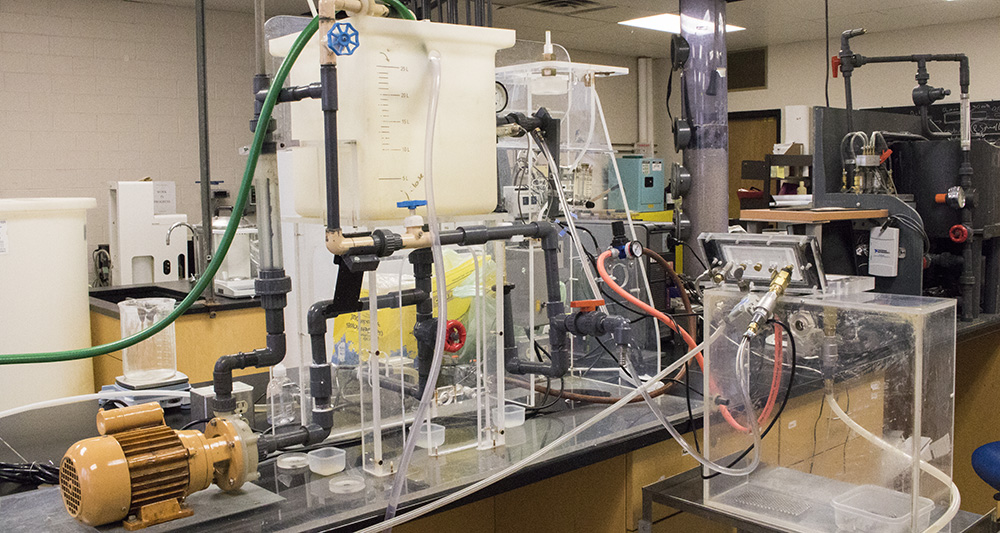

From high-performance computing stations to large-scale bioreactors, Toronto Metropolitan University’s laboratories and facilities give you the opportunity to perform sophisticated research and experimental investigation.

Principal Investigator: Dae Kun Hwang

St. Michael’s Hospital

Our research group develops novel microfabrication methods based on microfludics, photolithography, and free-radical polymerization to generate functional polymeric materials for various applications such as sensing, cancer spheroid culture, cancer detection, anticounterfeiting, and energy storage. We investigate and manipulate flow in confined channels at small scales to obtain optimum processing control and to engineer material functionality and property.

We also perform modeling and simulation to better understand and investigate fundamental issues arising from our research. We are particularly interested in creating microparticles, membranes, and functional surfaces. Our ultimate goal is to develop a robust and low-cost tool to design and produce functional polymeric materials that meet current and future demands.

Principal Investigator: Stephen Waldman

Li Ka Shing Knowledge Institute (LKSKI), St. Michael's Hospital

Research in this lab focuses on the engineering of functional cartilage suitable for joint resurfacing, spine repair, and ear and tracheal reconstruction. The lab features equipment required for cell and tissue culture, bioreactors, mechanical testing, mechanical stimulation of cells, and biochemical and bioanalytical assessments of developed tissues. Students and researchers also have access to the resources available at the LKSKI, which includes a flow cytometry core facility, 3D printing and bioimaging technology.

Visit the Cartilage Tissue Engineering Laboratory (external link, opens in new window) website.

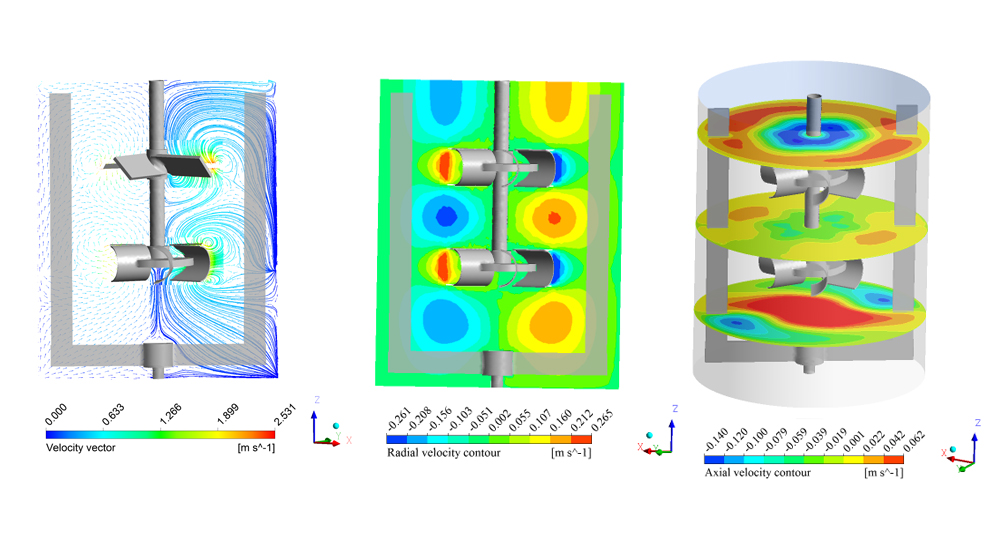

Principal Investigator: Farhad Ein-Mozaffari

KHN-107D4

Both commercial and open-source software are used in this lab, such ANSYS Fluent, OpenFoam, EDEM and LIGGGHTS to simulate various single-phase and multi-phase flow processes, including complex mixing operations, powder blenders, fluidized beds, bioreactors and conveying systems. The lab also employs CFD-DEM coupling to simulate multiphase solid-fluid systems.

Principal Investigator: Philip Chan

KHN-107D3

In this lab, research is ongoing in the mathematical modeling and computer simulation of complex fluids and advanced materials such as liquid crystals and polymers. The lab is equipped with personal computers serving as terminals for access to high-speed workstations and state-of-the-art advanced research computing systems for high-performance computation and data storage.

Principal Investigator: Jiangning Wu

KHN-109

Applications of oxidation/ozone technology in industrial wastewater treatment and polymeric membrane surface modification are the focus of ongoing research in this lab. Researchers have access to an ozone generator, ozone monitor, UV-Vis spectrophotometer, goniometer and Instron Universal Testing Machine.

Principal Investigator: ChungHyuk Lee

KHN-111

At FEEL, we study fluids and electrochemical engineering, with clean energy applications such as fuel cells and electrolyzers. Our research focuses on (1) understanding mechanisms of performance and durability losses in these systems using experimental diagnostics coupled with computational tools and (2) designing and creating materials for next generation fuel cells and electrolyzers.

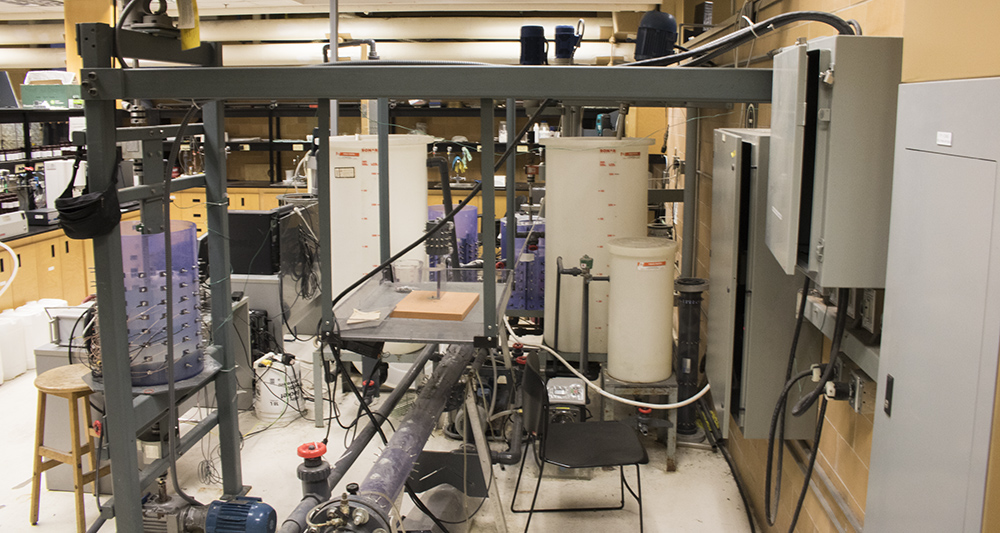

Principal Investigator: Farhad Ein-Mozaffari

KHN-1

This advanced facility enables you to investigate multi-phase flow systems, non-Newtonian fluid flow, complex mixing operations, and granular flow. It is equipped with a state-of-the-art particle-size analyzer, an ultrasonic Doppler velocimeter, and a research-grade rheometer. You also have access to electrical resistance tomography, an automated vision analysis system, a variety of batch and continuous mixing systems, static mixers, powder blenders, and gas-lift reactors.

Principal Investigators: Simant Upreti and Ali Lohi

KHE-133

This laboratory provides high-speed computing and testing facilities to develop Artificial Intelligence-based strategies for the modeling, simulation, optimization and optimal control of chemical processes with a focus on sustainable process design, process integration, scale-up, and process enhancements.

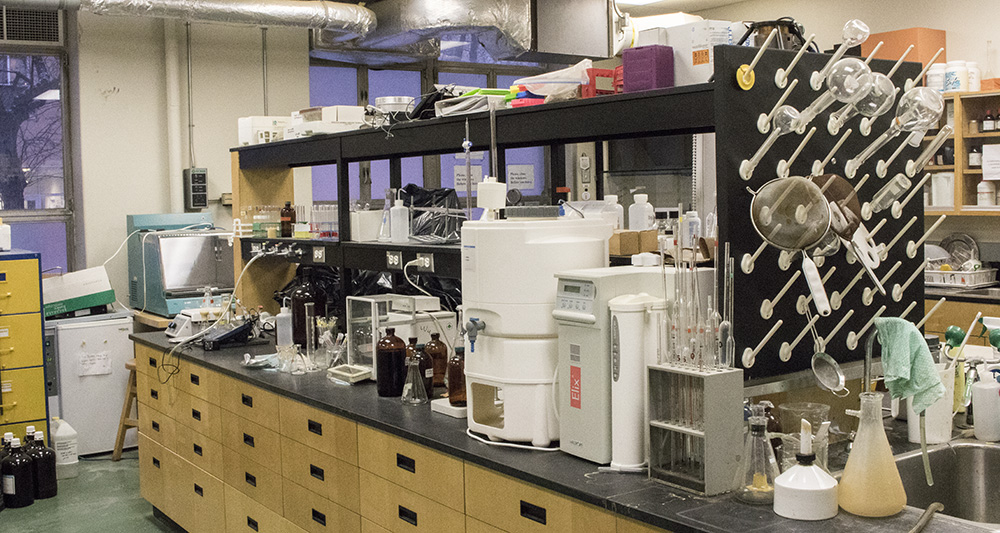

Principal Investigator: Mehrab Mehrvar

KHN-001

In this lab, you will study the treatment of industrial and municipal wastewater by advanced oxidation technologies integrated with biological processes. The lab is equipped with several experimental set-ups for wastewater treatment research, including aerobic and anaerobic bioreactors, photoreactors, sonophotoreactors, adsorption columns, and several small-scale reactors. It is also equipped with analytical instruments, including a respirometer, a total organic carbon/total nitrogen analyzer, a BET surface area analyzer, an incubator/shaker and a spectrophotometer.

Principal Investigator: Huu Doan

KHN-113

This laboratory is mainly utilized for membrane filtration research, including membrane fouling remediation in ultrafiltration processes. The equipment available to you includes a Micromeritic Tristar 3000 Analyzer for particle surface area and porosity measurements, the Malvern Zetasizer Nano Series for measurements of zeta potential of solution and flat surface, a UV-Visible spectrophotometer, and an ozone generator and ozone monitor.

Principal Investigator: Yaser Dahman

KHE-130

Key areas of research in this lab include green technology, nanotechnology, biotechnology, biomedical engineering, and bioseparation/separation engineering. A bioreactor, autoclave and biological safety cabinet (Class II) are available for your research purposes, as well as a stirred tank reactor system for polymerization studies, and different novel classes of internal and external airlift bioreactors. An XLW (PC) auto universal tensile tester is also available for investigating the mechanical properties of various flexible materials.

Visit the Nanocomposites and Biomaterials Engineering Laboratory (external link, opens in new window) website.

Principal Investigator: Hadis Zarrin

KHE-132A

In NLEET, you will work on nano-engineered research projects for clean energy storage systems and environmental remediation technologies. Synthesis and characterization facilities include a Gamry potensiostat to measure the electrochemical properties of batteries, capacitors and fuel cells; a gravity oven equipped with customized casting plates to fabricate nanocomposite membranes; an ultrasonicator to either disperse nanoparticles in liquids or break up bulky materials to nanosized structures; and essential synthesis equipment and chemicals to produce smart multifunctional nanostructures, microporous materials and polymer nanocomposites.

Principal Investigator: Chil-Hung Chen

KHE-132

This research lab gives you the opportunity to explore synthesis, characterization and application of porous materials (zeolites and metal-organic frameworks). Solvothermal synthesis approaches are engaged to modulate the crystal morphology of porous materials for better catalytic and gas separation performance. Rigorous characterizations are performed to elucidate the growth mechanism of porous materials under synthesis conditions. The equipment available for use includes autoclaves, synthesis ovens, a muffle furnace, a water polishing system (Type I), and a centrifuge.

Principal Investigator: Simant Upreti and Ali Lohi

KHE-131

This laboratory houses the following equipment: 1) a four-zone gasification/pyrolysis apparatus to produce bio-oil and synthetic gas from agricultural and food waste; 2) a high pressure extraction unit using supercritical carbon dioxide as the reaction medium; 3) a high-pressure view cell to determine equilibrium conditions of mixtures comprising solids and gas/liquid phases; 4) a labscale chemical plant for pH control; 5) a polymer injection molding system; and 6) a pressure decay setup to determine concentration-dependent gas diffusivities in liquids.

Principal Investigator: Ramdhane Dhib

KHN-113C

This research laboratory primarily focuses on the production of polymer materials. The research activity consists of conducting experimental and theoretical investigations of polymerization systems mainly in dispersed media, developing related process models and process control techniques schemes. The lab is equipped with a modern stirred tank reactor setup, which allows comprehensive investigation of polymerisation kinetics. The laboratory research has focused on the production of structured polymers using ATRP techniques, a variant of Living Radical Polymerization (LRP), in pilot-plant emulsion reactor, as well as focusing on mathematical process modeling and linear/nonlinear model predictive control (L/NMPC) of polymerization reactors, and of bioreactors for biodegradable polymers.

Principal Investigator: Nariman Yousefi

KHN-113

In this lab, we develop advanced multifunctional materials for addressing some of the most pressing global challenges such as water quality, sustainable energy, and accessible healthcare. Our goal is to achieve the best performance by self-assembling nanomaterials at macroscale, microscale, and nanoscale to obtain rationally designed, smart, and multifunctional structures. In doing so, we get inspiration by nature which has perfected the art of self-assembly through millions of years of evolution. Our research is at the intersection of chemistry, materials science, chemical engineering, environmental engineering, and biological sciences.

Visit the Yousefi Lab for Self-assembled Nanomaterials (external link, opens in new window) website.